I have been a sub-contractor and a contractor for over 30 years, and because of this I have gained a lot of construction skills. I often use sub-contractors as they are not only expert, but they are also very efficient in doing their particular job. With that said I am competent doing many of their tasks, abet a bit slower.

However, there is one area where I always yield to a subcontractor. That area is measuring a new countertop. Countertops are precision objects that are literally “set in stone.” A false measurement can result in a very expensive error

The sub-contractors that I have used for many years are expert at countertop measuring. In the past they would create a foam board template which served as a cutting/measuring guide. However, they now use a laser system.

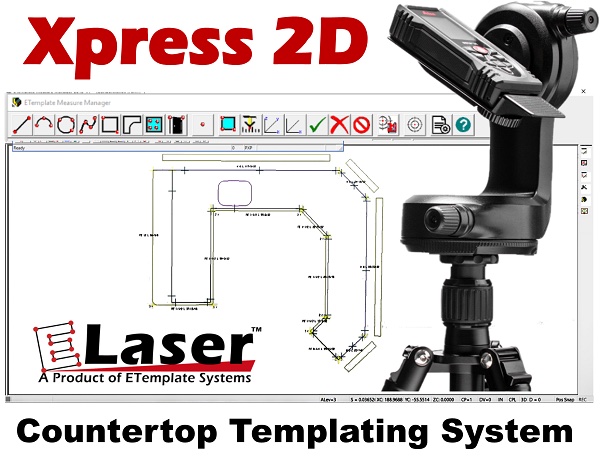

Laser measuring devices have been available for general contractors and DIY users for decades. However, this technology can be combined with software to create a 2D or 3D template. These devices are very accurate and make quick work out of measuring a complex countertop. They also allow for many measurements, which are needed as all walls tend to be less than straight. Their one downside is cost, which often exceeds $10,000.00 (not including the computer). See photos below.